S2K Commerce - Products Dropdown

S2K Commerce - Products Dropdown

Web Content Viewer - Blog

Web Content Viewer - Blog

Why Who Made Your Dental Face Mask Matters

When COVID-19 created an unprecedented demand for personal protective equipment (PPE), many countries were caught off guard. Without sufficient stockpiles of items such as masks, gowns and gloves, many frontline healthcare workers were forced to reuse disposable items or go without. As demand began to surpass available supply from reputable manufacturers, companies and individuals were eager to profit from the situation and began producing face masks. However, many had no medical device manufacturing experience and no knowledge of the regulatory requirements that are in place to keep healthcare professionals safe. Unfortunately, their masks did not provide adequate protection against virus transmission and some even contained potentially harmful materials* that put wearers’ health further at risk.

Producing medical grade face masks that provide medical professionals with safe and reliable respiratory protection requires extensive knowledge and experience. That’s why it’s critical to purchase respiratory protection only from a knowledgeable and experienced mask manufacturer that uses high-quality raw materials, state-of-the art manufacturing techniques and stringent quality controls that meet all regulatory standards.

Why who made your mask matters

Given the critical importance of reliable respiratory protection, two international standard-setting bodies, the American Society of Testing and Materials (ASTM) and the International Organization for Standardization (ISO), established stringent quality standards for all face masks intended for use in healthcare settings. In the midst of a pandemic of a virus that is as highly transmissible as Covid-19 and the current Delta variant in particular, choosing a mask that meets these standards is more important than ever.

What are ASTM standards for medical face masks?

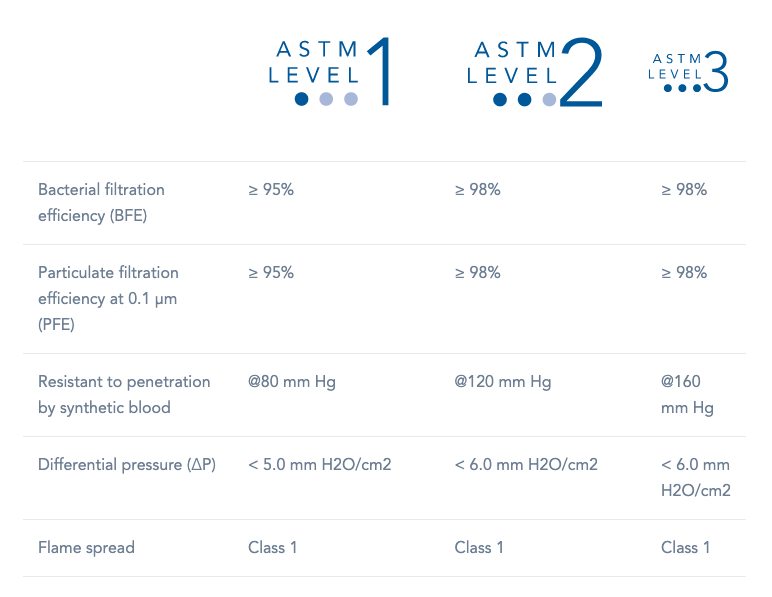

ASTM F2100-19 (2019) is the international standard for medical face masks. It classifies medical masks as providing Level 1, Level 2 or Level 3 barrier protection, with Level 3 providing the highest level of protection, based on the following criteria:

Criteria

BFE (Bacterial Filtration Efficiency)

BFE measures how well a mask filters out bacteria when challenged with a bacteria-containing aerosol. ASTM specifies testing with a droplet size of 3.0 microns containing Staphylococcus aureus (average size 0.6-0.8 microns). To qualify as a medical mask, a minimum 95% filtration rate is required. Moderate and high-level protection masks must have bacterial filtration rates greater than 98%.

PFE (Particulate Filtration Efficiency)

PFE measures how well a mask filters out sub-micron particles (similar to viruses). The higher the percentage, the better the mask filtration. ASTM F2100-19 specifies that a particle size of 0.1 micron be used for testing.

Fluid Resistance

Fluid resistance measures a mask’s ability to minimize the amount of fluid that penetrates the mask as the result of a splash or spray. ASTM F2100-19 specifies testing with synthetic blood at pressures of 80-, 120- or 160-mm Hg to qualify for low, medium, or high fluid resistance. These pressures correlate to blood pressure: 80 mm Hg = Level 1 120 mm Hg = Level 2 160 mm Hg = Level 3

Delta P (Pressure Differential)

Delta P measures a mask’s air flow resistance and provides an objective measure of its breathability. The Delta P is measured in units of mm H2O/cm2. The lower the value, the more breathable the mask. ASTM Delta P requirements: Level 1 masks: less than 5.0. Level 2 and 3 masks: less than 6.0

Flame Spread

Because oxygen, heat and fuel sources are found in most hospital settings, ASTM F2100-19 standards require that masks be tested for flame resistance. All hospital masks must withstand exposure to a burning flame within a specified distance for 3.5 seconds.

What are the 3 ASTM protection levels?

ASTM-rated masks are classified according to the level of barrier protection they provide, based on the five criteria listed above, with Level 1 masks providing the lowest level of protection and Level 3 masks providing the highest:

What ASTM protection level do you need?

It is recommended that you choose your mask’s barrier protection level based on its intended use:

ISO Standards

In addition to meeting ASTM performance criteria, all medical face masks must comply with the International Organization for Standardization (ISO). ISO 10993-5 and ISO 10993-10 are the international standards for cytotoxic and skin sensitivity testing. This testing aims to ensure that no part of the mask that comes into contact with the wearer’s skin contains potentially harmful materials.

When you wear a mask all day, comfort matters

While newcomers to medical mask manufacturing have been eager to produce the fastest and cheapest masks, reputable medical mask manufacturers have a vested interest in maintaining their reputation for providing safe and reliable respiratory protection that is also comfortable to wear, even during the longest shifts.

With healthcare professionals currently wearing masks for longer periods of the day than ever, mask breathability and comfort are more important than ever. Mask experts like Medicom, a North American company that has been manufacturing PPE for over 33 years, know how to produce medical masks that not only provide reliable respiratory protection, but that are also highly breathable and gentle on skin.

Medicom developed its specialized medical mask expertise in close collaboration with the healthcare professionals who wear them. By investing in ongoing research and development, premium raw materials and state-of-the art machinery, the company continues to produce innovative, premium-quality masks that meet the needs and preferences of those who wear them.

The Medicom SafeMask® Premier™, made in Augusta, Georgia, and the Premier Elite™ ProShield™ with an integrated visor for added protection.

For those who find it hard to breathe or feel claustrophobic in ordinary masks, Medicom developed the SafeMask® FreeFlow™ with Air Space™ technology. This mask has innovative contoured pleats that create a unique pocket between the face and the mask to allow air to flow freely.

Breathability is not the only key to comfort. Wearing a mask all day can be irritating to the skin on the face and ears and this is especially true for those with sensitive skin. That’s why Medicom developed the SafeMask SofSkin® Earloop Mask to provide reliable barrier protection without irritating sensitive faces. SafeMask SofSkin® has a unique lightweight, breathable cellulose-blend inner layer that is designed to soften with wear and keep face dry and cool, making it ideal for even the most delicate skin.

While respiratory protection is serious business the experts at Medicom have not lost their sense of fun. Many of their most popular mask lines are available in a variety of colours, ranging from traditional to vibrant. You can view the complete portfolio of masks made by the medical mask experts at Medicom on their website at Medicom.com or in this convenient downloadable Mask Quick Reference Guide.

Today, as the COVID-19 Delta variant is causing infection rates and hospitalizations to increase, students head back to school and flu season is around the corner, increased demand for medical masks is easy to foresee and North America is better prepared to supply the reliable respiratory protection healthcare workers need thanks to companies like Medicom.

Since the beginning of the pandemic, Medicom has partnered with governments across the globe to ensure local supply of medical masks for their frontline workers. In 2020 alone, the company opened new manufacturing facilities in France, the UK, Singapore, the US and Canada. The company will continue to help build North American mask stockpiles to meet current and future needs by building a new plant in Canada to produce the raw material needed to produce surgical and respirator masks, as well as a new PPE research and development center. This global footprint, in addition to its over three decades of infection control expertise, make Medicom the right choice for all your respiratory protection needs.

Whatever mask you choose, be sure you’re wearing it properly

A medical mask can only protect effectively if it is worn correctly. That means there should be no gaps along the sides of the mask between the mask and the face and that the mask should extend from the bridge of the nose to the chin. It is critical that the mask covers not only the mouth, but also the nose. To ensure adequate coverage of the nose, masks should not be worn below or at the tip of the nose.

For simple step-by-step instructions, watch this short video.

DHP proudly offers Medicom products. Read more about safe PPE at The Medicom Blog.